A digital twin of a product gives businesses the ability to take stock of a virtual representation of the elements and the dynamics that affect the operations of an IoT-connected product.

The product can be something as simple as a small pump or something as complex as an airplane. Even a human being connected to the right IoT sensors can be digitally twinned for a purpose!

In the last seven days, I’ve fortuitously connected with leaders in two cutting-edge product firms working in totally contrasting sectors, who have been applying the ‘digital twin’ concept in different aspects of their product lifecycle.

The Heros of This Story

The first company I connected with was Michigan-based Detroit Engineered Products – a leading engineered product development firm operating in the manufacturing sector. They provide their customers with the necessary tools and tech for creating a digital twin of their products so that they can do testing and development in a virtual environment.

The second company I connected with was Twin Health – a healthcare platform that has created a digital twin of the human body itself to simulate and understand our metabolic activity, which helps us to control and fight diabetes.

Though there are several sectors that are experimenting with digital twin tech, my aim today is to bring you reliable information straight from the experts so that you can derive insights that could help you use the digital twin concepts in your product lifecycle.

Digital Twins in Engineering Products

Shirin Hameed, the CMO of DEP describes a digital twin as essentially an “enabler to convert a physical asset into a numerical asset” that is “built to exist along with the life of the product, and optimize the real physical asset.”

She says, “A digital twin can be a model of a component, a system of components, or a system of systems- such as pumps, engines, power plants, manufacturing lines, or a fleet of vehicles. In the Digital Twin, the actual product and the virtual model are no longer separate, but twin-like. They exchange data and interact through IoT.”

But Shirin makes it clear that digital twins are not intended to replace a physical object, but merely to inform on its optimization.

“It is a digital duplicate that represents a physical object or process. It would typically be used for operational optimization, predictive maintenance, or anomaly detection, and are naturally extremely useful in remote, sensitive or difficult-to-access locations.”

Industry 4.0 brought tremendous changes to the product development process and provided the framework for designing products that were connected, at times 3D printed. In Industry 5.0, the digital twin is expanding the framework and transforming it to another level.

Digital Twin in Healthcare - Managing Diabetes

Managing Type 2 diabetes can be challenging as each individual’s metabolism functions differently, making it difficult to customize treatment for them individually.

This is where Twin Health – a precision healthcare platform has made use of the digital twin concept to come up with a whole-body Digital Twin to an individual’s metabolism using real-time data from wearable sensors.

Maluk Mohamed, the Co-founder, V.P. (Research) at Twin Health says, “Powered by AI and ML, the whole body digital twin gives a dynamic representation of each individual’s metabolism in real-time with the help of non-invasive wearable sensors”

Twin Health’s platform leverages the whole body Digital Twin technology, with AI and the IoT, to integrate the multi-dimensional data generated from our body, to give precision nutrition, sleep, activity, and breathing guidance via their app.

Using digital twin technology, Twin Health’s randomized control trial has been proven as the world’s first for reversing chronic metabolic disease using digital twin technology. In December 2021, Twin Health was named to C.B. Insights Digital Health 150 – C.B. Insights’ annual ranking of the 150 most promising digital health startups in the world.

The Rise of Digital Twin Technology

Retail:

French supermarket chain Intermarché has created a digital twin of its store based on data from IoT-enabled shelves and sales systems. This enables its store managers to easily manage inventory and test the effectiveness of different store layouts.

Automobile:

Digital twins are handy for autonomous vehicle companies like Tesla. The self-driving cars of today contain numerous sensors that collect data about the vehicle and the environment surrounding it. Creating a digital twin of a car and testing every aspect of the vehicle is helping companies minimize damage and injuries. Some applications of digital twins in the automotive industry are road testing and vehicle maintenance.

Urban Planning:

Aguas do Porto (AdP), a Portuguese utility organization, is responsible for the water supply in the city of Porto. AdP uses digital twins to forecast flooding and water quality issues, improve city services and responsiveness, and ensure the resilience of water infrastructure.

Renewable energy:

Energy is another sector benefitting from digital twins. GE has reported that its wind farms have increased productivity by as much as 20% with the help of digital twins. The real-time information fed to their digital replicas from sensors on each of the turbines enables more efficient designs and even suggests changes for making each active turbine more effective.

What’s Next for Digital Twins?

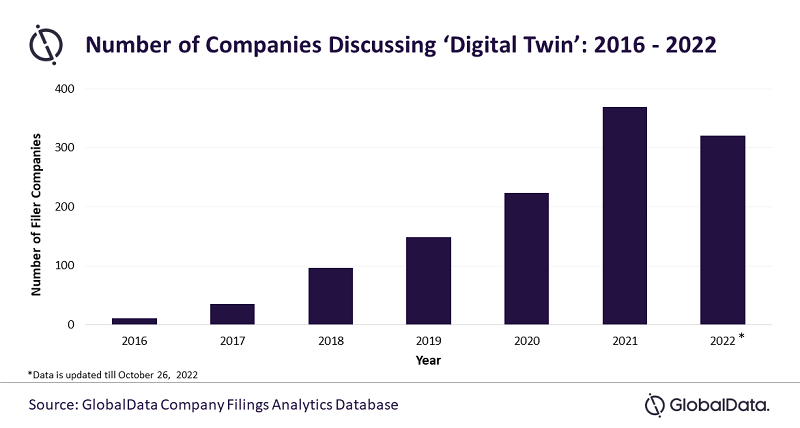

According to GlobalData’s Company Filing Analytics Database, the number of companies that mentioned ‘digital twin’ technology in their company filings increased by 43% in 2022 when compared to 2020.

The data and analytics company notes that the sectors with the most companies discussing ‘digital twin’ include technology, construction, oil & gas, and mining.

The reports also show that more and more IoT platform vendors will integrate simulation platforms, systems, and capabilities to create digital twins, and manufacturers will use the technology to conduct process simulations and scenario evaluations.

Since it has become easier and cost-effective to create a digital twin, companies across sectors are increasingly implementing the technology to boost productivity, innovate the manufacturing process and reduce costs. While the reasons for a digital twin may differ from sector to sector, digital twin technology can benefit businesses in all industries.